Product introduction

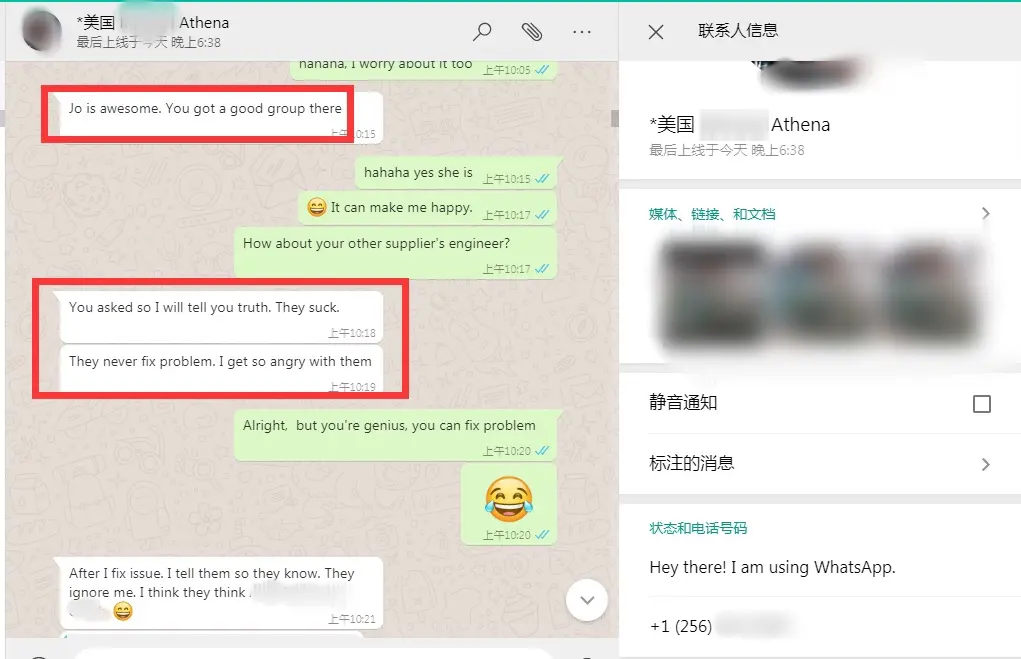

CUSTOMER FEEDBACK

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

OUR EXHIBITION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

undefined

Ratings & Reviews

A***i1

Oct 04,2024

Regarding the Tradeshow. Thank you for sending engineer, He is extremely Knowledgeable and had both printers printing beautful. The new Cobra pinter is defnitely a great industrial printer!! Now we have a start to sell this printer!!!!!

l***i2

Oct 08,2024

You are teaching me well. I need to know more than average customers do. l'l be assistimg them as you do for me here in US with customers. Cobra training video is excellent.

121-1251

Aug 13,2024

Oh, it's very good ! I have 6 printers, All focus inc, they make very very good job and helped my business grow.

12***i

Oct 03,2024

The print quality is excellent, I am so happy, I assembled machine and made my first print in less than 2 hours, I will consider ordering 2 more Cobra by the end of this year.

l***i

Oct 16,2024

Regarding the Tradeshow. Thank you for sending engineer, He is extremely Knowledgeable and had both printers printing beautful. The new Cobra pinter is defnitely a great industrial printer!! Now we have a start to sell this printer!!!!!

Online Message

Ready to grow your business? Your next great business opportunity starts with an inquiry.